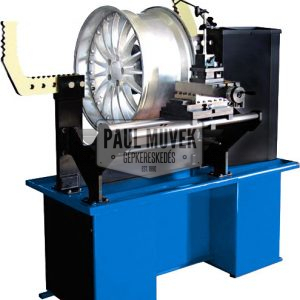

Description

Professional rim straightener and repair with lathe. Not only push but pull. Hands-free operation.The best rim straightening equipment there is.

NO ONE ELSE HAS THIS MESURE AND TWO ARMS REPAIR TECHNOLOGY!

A high-tech machine with digital measuring to find the smallest differences, dents. The best for any business offering rim straightening and repair on any level.

- There are two pressing pedals. These pedals can be controlled separately with 8 directional joystick. The direction of the pressing pedals mounted on, can be calibrated as required. While one of the pedals is used as fixing support, with the other pedal, the leveling procedure can be done much faster and properly. During pressing, digital mesurement prob provides to see the mesuremental value of pressing by position it on the rim in the mean time.

- Mesurement prob can be simply positioned with the joystick which is on the controll panel by the help of sensible lineer slides and 2 axes motor controlling system.

- The probe, which is positioned on the rim with joystick, can mesure the up –down flexures and also, in the mean time the right-left precessions on the rim due to its patented design.While it shows the millimetric value of the pressing of the pressing needs to be done, it also indicates the pressing direction with the lights shaped as arrow.

- It has a strong and rigid turning system which specially designed. Turning support can be positioned as required, due to its threaded mile on the turning system. After the calibration of direction and position of support, the turning system can be applied.

Some of the key features:

- The latest and newest technology in rim repair

- The probe, which is positioned on the rim with joystick, can mesure the up –down flexures and also in the mean time the right-left precessions on the rim due to its patented design

- It has a strong and rigid turning system which specially designed

- The machine equipped with two pressing pedals. These pedals can be controlled separately with an 8 directional joystick

- The direction of the pressing pedals mounted on, can be calibrated as required

- Has 2 Heads – Multi-function support positions

- Robust and reliable machine with built-in lathe

- Rim sizes: 12″-28″

- Lots of standard accessories

- Multi function support positions

- Adjustable lathe

- Gear box driven

- Multi function joystick

- Electronic rotate control

- Digital measuring – the digital gauge shows how much the rim is bent and the arrows indicate the direction of the damage.

- Approx. 10-13 minutes repair time/rim

- Has two different engines one hydraulic for the piston and one working to spin the rim and for the lathe

- Multi function support positions for the pushing heads

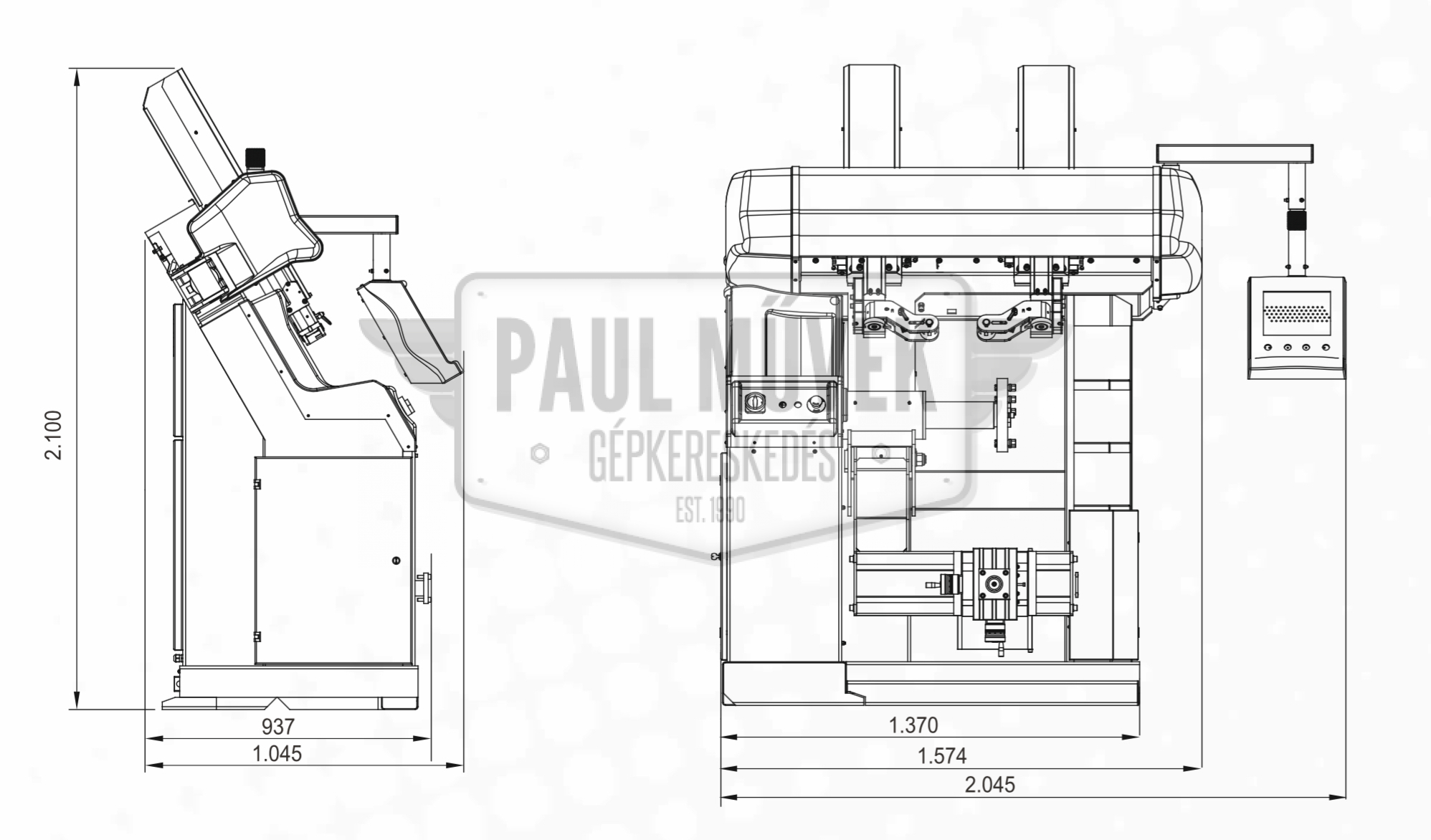

Specifications:

- Rim sizes: 10″ – 28″

- Power: 400V 60Hz 3 phases

- Dimensions:

Height: 6.9feet/2100mm

Depth: 3.07feet/937mm

Width: 5.16feet/1574mm - Weight: 2100lbs/940kgs

- Hydraulic working pressure: 140bar

- Hydraulic engine: 1.5Kw/2Hp

- Working engine: 1.1Kw/1.5Hp

- Rotating speed: 5-98rpm

Optionals:

- Quick Clamp mounting system

Quick Clamp mounting

Quick Clamp mounting 2

- Extended pushing head set

Extended pushing head set

Extended pushing head set 2

- Electric rim heater system (6000W)

Electric rim heater system

Electric rim heater system 2