Description

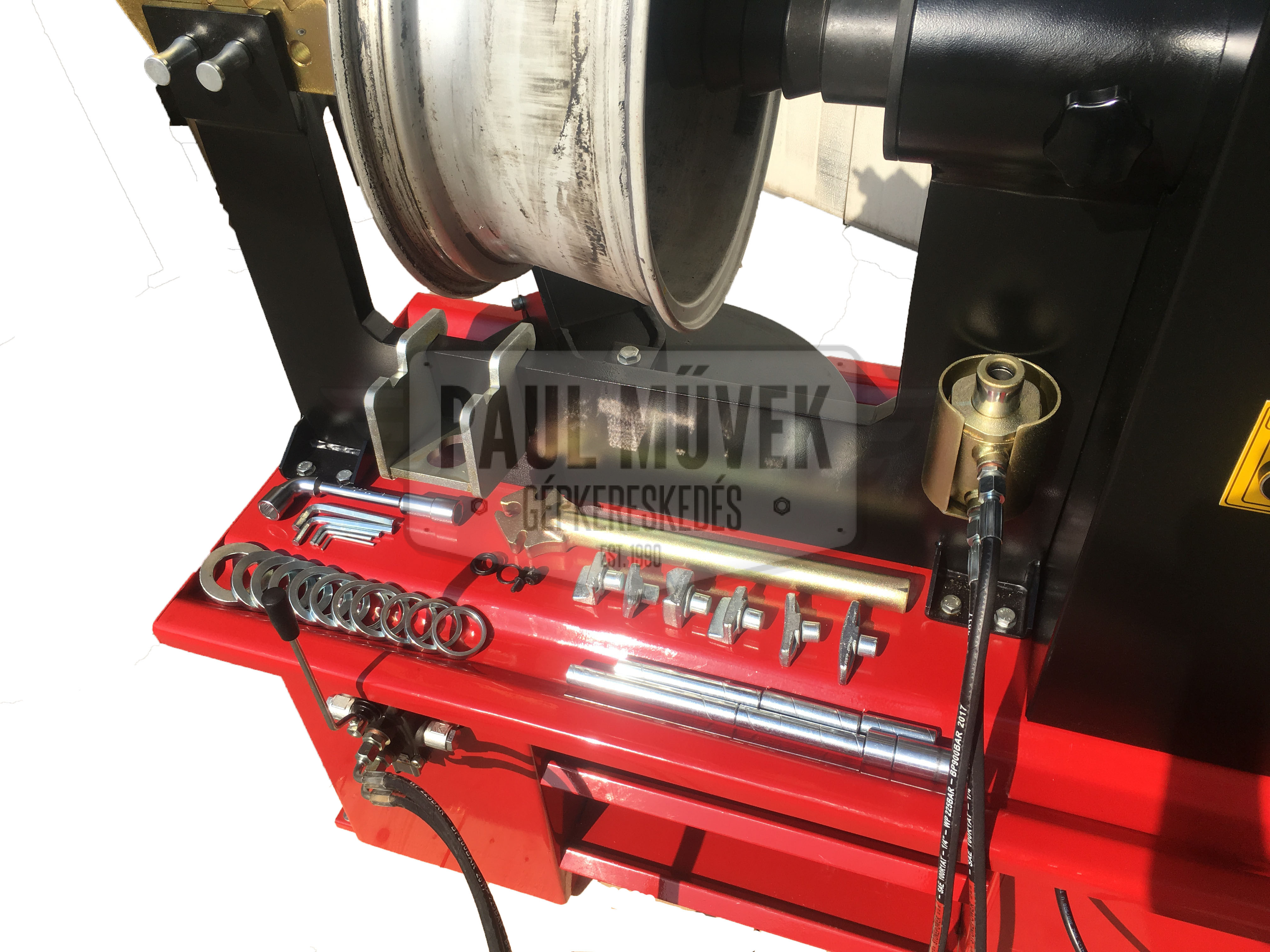

Fix rims with this rim straightener and repair machine! This is an entry-level machine with lathe accessory and can do all wheel repairs.

The machine is perfect for any tireshops or rim repair shops. Deals with bents and with the built-in lathe it is also capable of doing the tidying and refinish. It also can be equipped with the clean and polish kit so with that you can give a nice refinish for the lathe.

Features

- Rim diameter: 10″- 24″

- The only difference between the Kaiser 5700 and the Kaiser 5400 is the lathe. While the Kaiser 5700 has a turning lathe, the Kaiser 5400 has a sliding one. Apart from this there is no real difference between the 5400 and the 5700.

- Lots of standard accessories

- Standard big support kit

- V-belt driven (unlike the gearbox types it needs maintenance sometimes)

- Equipped with two engines – one for the hydraulics(the pressing head) and one is the working engine which spinns the rim

- Approx. 15-20 minutes repair time/rim depending on experience

- The optional clear and polish kit can be attached

- Turning lathe

Specifications

- Rim diameter: 10″- 24″

- Dimensions: Height: 5.26feet/1605mm

Depth: 3.602feet/1098mm

Width: 4.625feet/1410mm - Weight: 797lbs/361kg

- Working pressure (hydraulic): 140bar

- Hydraulic engine power cons: 0.55Kw/0.75Hp

- Working engine power cons: 0.75Kw/1Hp

- Rotating speed: 250rpm

- Power: 380V/ 50-60hz/ 3phase