Description

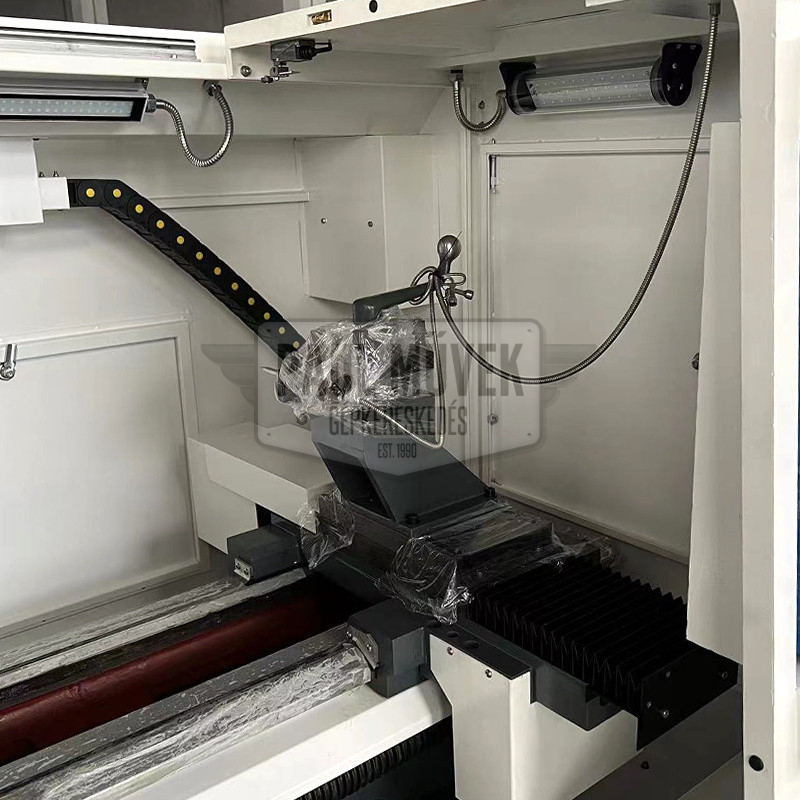

4TH GENERATION CNC LATHE LIGHT METAL WHEEL CUTTING DEVICE (14″-26″). DISCOVER DIAMOND CUTTING!

- An economical choice for new workshops and start-ups

- Automatic processes

- 2-minute scanning time

- Total cutting time of up to 15 minutes (from start to finish)

- Clamping range of 14″-26″

Compact size, small footprint, enormous capabilities and ease of use. These are the hallmarks of our latest diamond lathe.

The GAMMAGT CNC26E is the latest version, which has increased the rim size (26″), but thanks to its new design, the machine’s dimensions and weight have been significantly reduced, resulting in a more compact lathe that takes up less space.

The latest CNC lathe significantly reduces the time required for rim repair thanks to its improved measuring and cutting system and built-in touch screen. What’s more, there is no longer any need to transfer data, as the machine can handle all the data itself. Our latest machines are now in their 4th generation and enable even faster and more precise work.

Just take the measurements and start cutting!

Since the equipment automatically records the wheel profile data, you no longer need a separate computer to enter the exact data into the machine. The CNC machine software can handle and execute the entire process. This allows you to restore even more rims to their original condition in the same amount of time.

Latest 4th generation equipment

Our wheel disc lathes feature some of the latest 4th generation technology on the market, making the measuring and cutting process faster and easier than ever before.

The scanning probe is capable of recognising even extremely complex wheel designs and adjusts the measuring ranges accordingly.

The 4th generation technology includes the option of adjusting the feed and rotation speed at any time, allowing any desired cutting surface to be created, whether it is a mirror-finish or a heavily grooved surface.

The steps of the process are as follows:

- The machine digitally records the data during measurement

- The diamond-tipped cutting blade cuts the surface of the wheel

The 15″ touchscreen and Windows 7 operating system ensure easy and convenient operation.

Thanks to its design, the measuring needle enables more accurate measurements than ever before.

We provide a one-day training course to familiarise you with the machine.

Technical data:

Model: GAMMAGT CNC26E

- X-axis travel: 365 mm

- Z-axis travel: 500 mm

- X-axis rapid traverse: 10 m/min

- Z-axis rapid traverse: 10 m/min

- Cutting feed speed range: 0.005~100 mm/r

- X, Z axis position accuracy: 0.01 mm

- X, Z axis repositioning accuracy: X–0.007 mm; Z–0.008 mm

- X, Z axis movement: Servo motors

- Max. turning diameter: 820 mm

- Max. wheel width: 450 mm

- Chuck type: 3 jaws, 12″

- Clamping rim size: 14″ -26″

- Rotary motor power: 5.5 kW

- Motor speed: 0 – 750 rpm

- Max. measuring depth: 110 mm

- Machine dimensions (L x W x H): 2010 x 1350 x 1530 mm

- Packaging dimensions (H x W x D): 2180 x 1500 x 1870 mm

- Net weight / Gross weight: 1500 kg / 1600 kg

- Power supply: 3-phase / 380 V / 50-60 Hz