Description

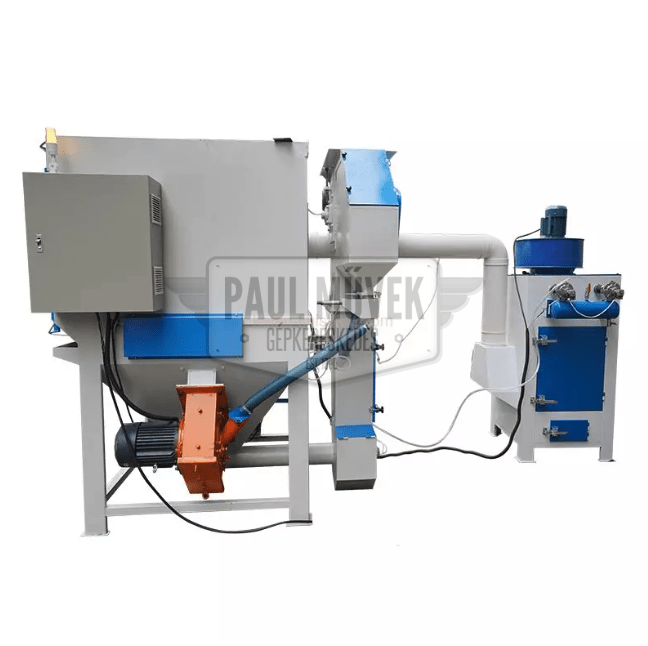

The KFWSB1 uses shot blasting technology to prepare light alloy wheels for polishing.

The shot blasting machine is an automated, labour-saving system that significantly simplifies the wheel cleaning and finishing process. The shot blasting machine gives the surface of the alloy wheel rim a roughness that ensures good grip and perfect powder coating application.

How does the shot blasting machine work?

The shot blasting machine is not powered by compressed air, but electromechanically, and uses a high-speed rotating wheel to eject steel shot at high speed and with high flow, thus exerting greater force on the surface.

Turbines positioned at the correct angle blow out steel shot and clean the surface of the components and wheel rims.

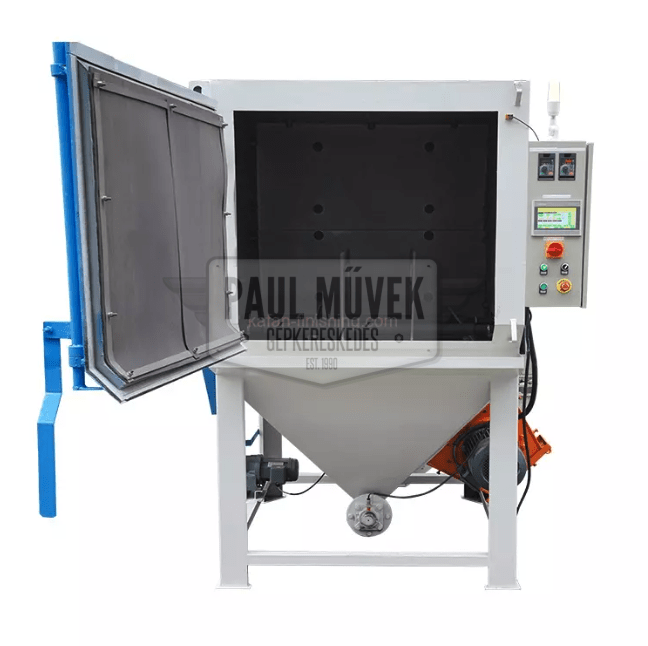

The wheel rim is placed in the chamber, where the process is fully automatic and can be controlled by a timer.

One wheel rim can be blasted at a time, which takes only 1-3 minutes.

Equipment structure

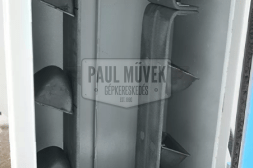

Projectile blasting chamber

The projectile blasting chamber, specially designed to hold the alloy wheel, consists of a protective bracket and two rollers for continuous rolling of the wheel, ensuring thorough cleaning and washing.

- Roller drive power: 400 W

Bearing head: 1 set

The head is designed for complete shot blasting of the wheel to be cleaned and minimises the empty throw of steel shot based on the coverage of all wheels to be cleaned.

Drive power of the wheel head: 7.5 kW (frequency controllable)

Elevator: Drive mechanism: 1 set

The elevator operates via a belt. A container attached to the conveyor belt scrapes the wasted blasting projectiles from the bottom of the elevator and feeds them to the top, where they are driven by the elevator motor. Finally, centrifugal gravity causes the pellets to fall into the separator. There is an access door on the exhaust cover for easy maintenance and replacement of wear parts.

- Elevator power: 1.5 kW

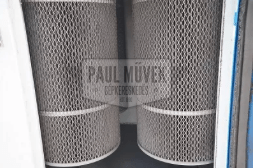

Filter dust collector: 1 set

Uses new, advanced filter material. Dust cannot penetrate the filter material, which is characterised by low resistance and easy cleaning, and has a filtration accuracy of 5μm. Dust removal efficiency is up to 99.5%.

- Air flow: 6800m3/h

- Fan motor power: 2.2KW

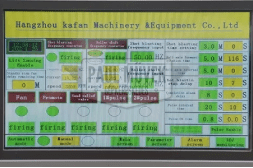

PLC electric control: 1Set

The electric control system is convenient for troubleshooting. The operator can start each functional component in sequence or cycle through each functional component to test performance and operating status.

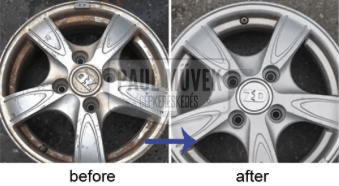

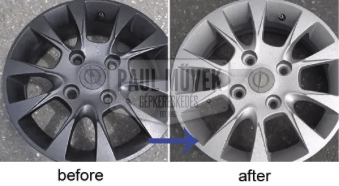

Wheel disc shot blasting applications

The wheel disc shot blasting machine is the first step in preparing the surface of the wheel disc. It is particularly suitable for removing old paint or for removing corrosion, rust and limescale.

In addition, the wheel rim is given a certain roughness during the process, which is necessary for preparing it for subsequent painting or powder coating.

Technical data:

- Cabinet dimensions: L1300 * W1300 * H780mm

- Equipment dimensions: L1720*W3658*H2265mm

- Wheel size: Diameter: 700 mm / Width: 500 mm (or smaller)

- Control system: PLC

- Rotation speed of rollers: Adjustable

- Blow-off speed: Adjustable

- Dust separator type: Dust filter: Flame-resistant filters

- Power supply: Electric

- Blower head power: 7.5KW

- Fan motor power: 2.2KW

- Roller drive power: 400W

- Lifting system power: 1.5KW

Installation requirements

- Power: 380 V / 3 phases / 50 Hz + socket combination box with appropriate fuses;

- Compressed air: –

- Ensuring the unloading process and the operating site

- Place the machine on stable, level ground.

Useful information:

Can only 1 wheel be sprayed at a time?

Yes, one wheel can be worked on at a time, covering the entire surface. The wheel does not need to be turned.

If you want to treat several wheels at the same time, we can also offer larger shot blasting machines.

How long does it take to shot blast 1 wheel?

It takes about 1-3 minutes to spray one wheel. High-efficiency equipment.

What is the power source for the wheel blasting machine?

It is airless and electrically powered, so there is no need to work with an air compressor.

After connecting to the power source, it starts working with a total power of about 13KW.

How often does the dust collector need to be replaced?

It depends on use. Generally, every 6-9 months.