Description

PK1 high-pressure sandblasting machine from PMJ in Poland. A cost-effective choice for paint removal from wheel rims and paint preparation.

With its durability and functional solutions, the PK1 high-pressure sandblasting cabin meets even the most demanding user requirements.

The use of a pressure tank makes the sandblasting effect five times more effective than in injector sandblasting cabinets. Abrasive materials such as sand, corundum, quartz, glass, steel balls, stainless steel balls, etc. can be used.

The sandblasting cabinet can be used in wheel rim refurbishment companies, car parts regeneration companies, in industry and wherever a part needs to be quickly, easily and cheaply cleaned of corrosion or old paint.

The sandblaster is made of 3.4 and 6 mm thick structural steel, which ensures its strength and long service life.

The machine is equipped with a dust removal system with automatic pneumatic cleaning of the cartridge filter, so only compressed air is required for its operation.

Other features that distinguish our product are a protective grille for the operator’s field of vision (if the lance slips out of the operator’s hand, it prevents the field of vision from being obstructed) and a vibration damping system, which makes it much easier to pour the abrasive when it is dirty or wet.

In pressure sandblasters, the use of a pressure tank results in five times more efficient blasting than in injector sandblasters.

MAIN ADVANTAGES OF THE PK1 SANDBLASTER

- Dust extraction system – Thanks to the dust extraction system with automatic pneumatic cleaning of the cartridge filter, only compressed air is required for operation.

- Durability – The rustproof cabinet is made of 3, 4 and 6 mm thick structural steel, which ensures durability and a long service life.

- Protective grille – Prevents damage to the operator’s field of vision if the lance slips out of their hands.

- Vibration system – Significantly facilitates the pouring of abrasive material in the event of contamination or moisture.

Sandblasting machines are suitable for use in automotive parts manufacturing companies, in industry, and in any place where a part needs to be quickly, easily and cheaply cleaned of corrosion or old paint.

Clemco tungsten carbide nozzle diameters: 4.8 mm, 6 mm, 8 mm.

The choice depends on the power of the compressor used.

If your workshop has a dust extraction system, you can order the cabinet without a dust extraction system at a lower price.

Internal dimensions of the cabin

- Width: 800 mm

- Depth: 800 mm

- Height: 900 mm

Applications

- Wheels – Steel, aluminium and even truck and bus wheels are no challenge.

- Brake calipers – Thanks to the spacious basket, up to 30 brake calipers can be cleaned in a single blasting and cleaning operation.

- Automotive turbos – The shot blasting machine is also ideal for cleaning turbines, significantly speeding up and facilitating the process.

- Other – Generators, suction nozzles, housings and much more

Technical data:

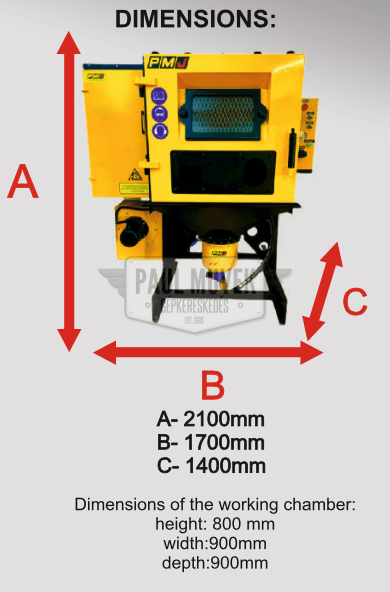

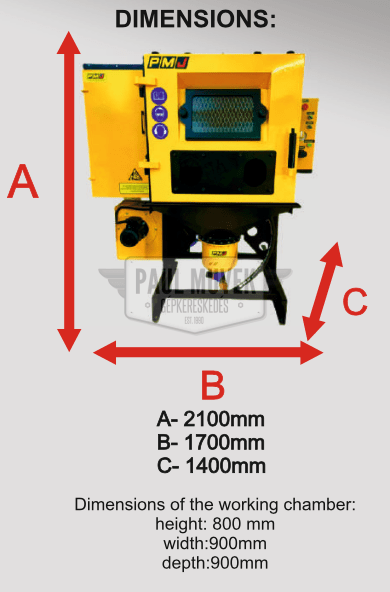

- Equipment dimensions: 2100 x 1700 x 1400 mm (L x W x H)

- Internal cabinet dimensions: 800 x 900 x 900 mm (L x W x H)

- Extraction capacity: 1.1 kW

- Maximum pressure: 8 bar

- Dust collection capacity: 2,200 m3/h

- Abrasive tank capacity: 20L

- Vibration motor: 200W

- Automatic filter cleaning: Yes

- Internal lighting: LED 2x50W

- Power: 400V / 3 PH / 50Hz (32A – 5-pin plug)

- Weight: 400 kg

Installation requirements

- Power: 380 V / 3 phases / 50 Hz + socket combination box with appropriate fuses;

- Compressed air: Yes

- Ensuring the unloading process and operating site

- Place the machine on stable, level ground.

Options

- –

Useful information:

- What is the difference between the RB7 and RB11 shot blasters?

The main difference between the RB11 and RB7 is the size, i.e. the RB7 is smaller than the RB11. The differences can be checked in the technical data.

The second difference is that the RB7 does not have an upper suspension. The performance is the same for both blasters. The differences between the devices are clearly visible in our demonstration videos.

- How much dispersion is required for the shot blasting machine and what is the initial load?

The initial load is approximately 15 kg and the shot consumption is approximately 0.8-1 kg/hour (the shot in the machine is only replenished as it is consumed).

- Are the machines available from stock or are they made to order?

Due to the various control options, the machines are manufactured to order. The delivery time for the machines is between 1 and 4 weeks.

- What grain size do the RB11 and RB7 gunpowder sandblasters work with?

The machines are made of S090, S110, S170, S230 quality round steel gunpowder or stainless steel and can be used with gunpowder of the same size. The use of ‘sharp’ broken gunpowder causes five times more wear on consumable parts.

- Does the shot blaster require compressed air to operate?

No, compressed air is not required for the shot blaster to operate.

- Can abrasives other than steel shot be used in the shot blaster?

There are no contraindications to the use of corundum, for example, but this is not cost-effective (the machine quickly breaks up the abrasive and it is sucked out by the dust collector).

- What is the difference between a shot blaster and a sandblaster?

The difference between a shot blaster and a sandblaster lies in the abrasive used and the mode of operation. A shot blaster uses metal balls, mainly for surface treatment of metals, often in automatic operation.

A sandblaster uses sand or other mineral abrasives to treat various materials, where the sandblasting is done manually. In addition, a shot blaster can automatically clean, grind or prepare surfaces, while with a sandblaster, the operator must perform the operations manually.

- What are shot blasters used for?

A shot blaster is a device that mechanically cleans, grinds and strengthens metal surfaces by means of shot blasting. It removes rust, paint and contaminants, prepares surfaces for painting or coating, and increases the wear resistance of the material.