Description

Installed, direct-driven screw compressor with YΔ-start, frequency controller and sound-absorbing housing. 11 kW. It keeps regulating the air supply between 500 and 1500 liters per min according to the current air demand, always as required at the set pressure.

By the frequency controller:

there is no idle, therefore, there is no unnecessary energy consumption, operational costs are lower. Due to the gradual start and stop, there are no current consumption peaks, thus reducing the high use of electrical and mechanical components, eliminating the pressure fluctuations, thus significantly increasing the service life of the equipment. Depending on the application, 15-30% of electrical energy can be saved compared to a conventional fixed-motion screw compressor with the same capacity and star and delta connections.

Advantage of the Permanent Magnet (PM):

the extended shaft of the compressor unit is also the rotor of the electric motor, so there is no need for bearings, transmission devices, e.g. V-belt, clutch, gear, etc. Due to the lack of bearings, additional 3-5% of electrical savings are expected, and there is a lower service costs compared to compressors with conventional power transmission structures.

Main features:

- MAM microprocessor control

- Automatic start/stop of the compressor

- It continuously monitors the current pressure value with the pressure transmitter and controls the operation of the compressor accordingly

- Displaying operating hours

- Registration of the service interval of the compressor and warning

- Protection against voltage fluctuations

- Protection against too low/high temperature

- Phase protection

- Monitoring the direction of rotation

- It indicates the arising defects on the alphanumeric- or LED displays and then shuts down the compressor before it is damaged.

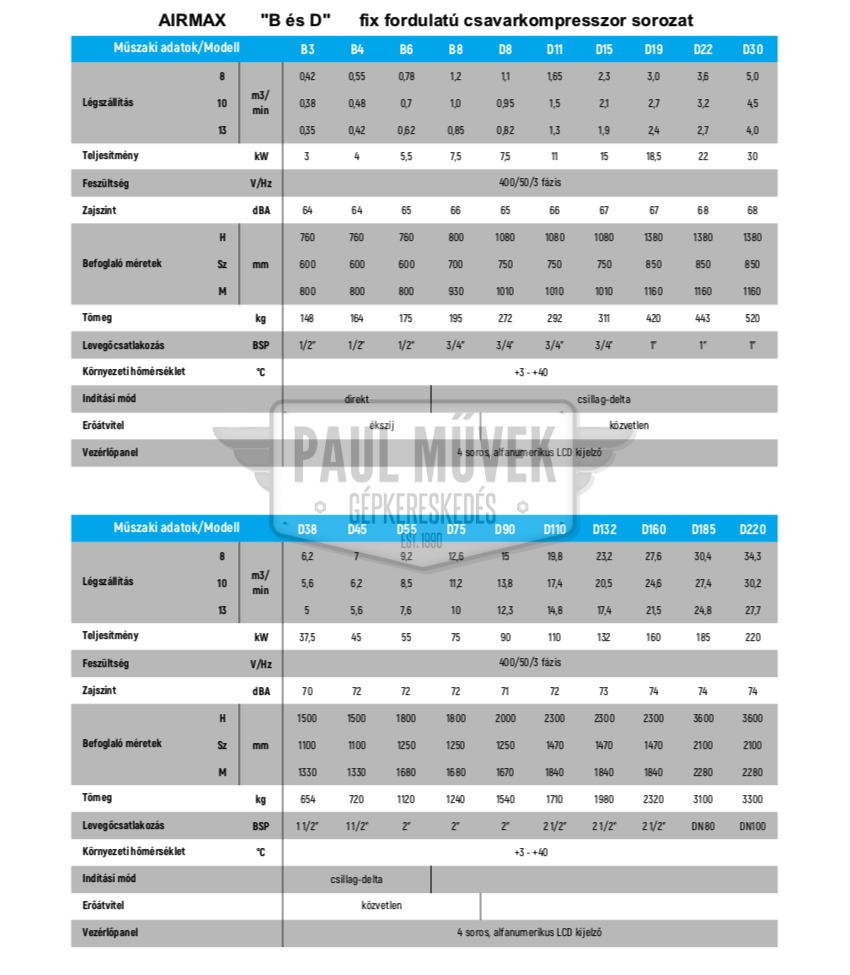

Specifiations:

- Performance: 11 kW/15 HP – 400 V/3 phases / 50Hz

- Air delivery: 500-1500 liters per min

- Pressure: available with pressures of 8-10-13 bars

- Noise level: 66 dBA

- Air connection: 3/4″

- Weight: 247 kg

- Dimensions: LxWxH: 1080 x 750 x 1010 mm

Available in versions of 8, 10 and 12 bars.