Description

High-quality, high-efficiency GAMMAGT FMA powder coating/powder spraying extraction booth, available in several sizes.

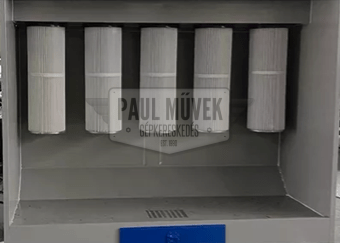

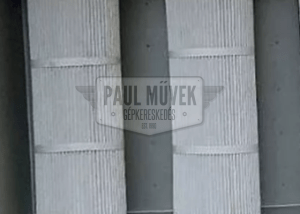

The GAMMAGT FMA powder coating extraction machine uses high-quality filter cartridges for efficient separation of powder and air.

It features a unique blow-back device that automatically cleans the dust at set intervals, ensuring excellent recovery efficiency.

Made of stainless steel and equipped with a rotating automatic blow-back system, the machine is easy to clean and facilitates quick colour changes.

The Gubot wheel dust recycling machine is designed for high dust recovery efficiency, following aerodynamic principles, with an external extraction system that sucks the scattered dust into the filter cartridge. This simple but effective design not only increases work efficiency, but also has a positive impact on the health and well-being of employees by reducing airborne contaminants.

Powder coating extraction cabins are special devices that extract dust and paint residues generated during powder coating, ensuring workplace cleanliness and environmental protection. During powder coating, the paint powder is sprayed onto the surface of the workpiece using a special spray gun, and the excess dust particles are removed by the extraction system.

Advantages

Highly efficient dust recovery system

The interior of the industrial powder coating extraction system is made of 1.2 mm cold-rolled steel with a CE-certified powder coating oven, which ensures a high powder recovery rate thanks to the structural design of the powder coating system.

Fast colour change capability

The curved welds of the automatic powder coating machine ensure that the powder coating booth panels are leak-proof. The cyclone in the multi-powder-free powder coating booth enables an efficient colour change system.

Closed powder coating system

The professional powder coating equipment combines filter cartridges with an automatic powder recovery system, smooth powder coating chamber surfaces and leak-free powder booth sealing material injection for easy colour changes.

Electrostatic powder recovery technology

The high transfer efficiency coating uses side airflow from industrial powder coating guns, maintaining stable airflow in the spray booth for optimum powder application.

Explosion-proof powder equipment

The energy-efficient powder coating oven has CE-certified explosion-proof lighting for powder coating safety, low energy consumption and easy maintenance.

Available models:

| MODELL | Inside dim. (cm) | Filters (pc) | Filters size | Filters material | Capacity (KW) | Wight(KG) |

| FMA100 | 100*120*200 | 2 | O: 32/Height: 90 | non wooden fabric | 2.2 | 80 |

| FMA150 | 150*120*200 | 3 | O: 32/Height: 90 | non wooden fabric | 2.2 | 100 |

| FMA200 | 200*120*200 | 4 | O: 32/Height: 90 | non wooden fabrict | 3 | 120 |

| FMA250 | 250*120*200 | 5 | O: 32/Height: 90 | non wooden fabric | 3 | 150 |

FEATURES

- Rim clamping capacity: 2-6 pcs

- Operating temperature: -40 °C / + 50 °C

- Efficiency: 80%

- Load-proof, additional fan: Optional

- Power: 380V / 3-phase / 50-60Hz

- Motor: 2.2-3 kW