Description

Compact, advanced, professional powder coating machine, which is essential equipment for achieving efficient, uniform and environmentally friendly coating. It uses the advanced electrostatic atomisation principle to ensure uniform and solid adsorption of powder coatings on the surface of workpieces.

Powder coating

The electrostatic powder coating machine is used to apply powder coatings to the surface of workpieces. Under the influence of static electricity, the powder adheres evenly to the surface of the workpiece and forms an even powder coating.

The powder coating is then baked at high temperatures, levelled and cured, resulting in a final coating with different effects depending on the type of powder used.

Compared to conventional painting processes, electrostatic powder coating machines deliver excellent results in terms of mechanical strength, adhesion, corrosion resistance and ageing resistance, while at the same time offering a more cost-effective solution for achieving the same high surface quality.

Spray gun control

Three preset programmes for the panel, deep corners and repainting.

The digital display shows the voltage/current value accurately.

Manual powder coating gun

The advanced spray gun ensures even powder distribution and good atomisation.

Simple and lightweight design, easy to use.

Large tank

The large 60-litre tank allows for large powder coating jobs.

The bottom of the tank is removable for easy paint replacement.

Features

- The spray gun uses a special spray gun with a built-in electrostatic generator, which evenly sprays the powder and prevents electrostatic backflow.

- The electronic components ensure the reliability and stability of the built-in voltage multiplier circuit.

- Precision integrated circuit, high efficiency, fast powder, good spray quality, manual and automatic.

- The two-way central air pump is used to increase the atomisation air flow and improve the coating quality and powder filling ratio.

- Equipped with a grounding safety circuit to ensure the safety of workers and machinery.

- Stainless steel powder hopper, fluidising plate, high air permeability, easy to clean.

- Suitable for a wide range of powder spraying, epoxy (commonly used), polyester, metal powder, etc. Powder replacement is simple and quick, suitable for multi-colour spraying.

Advantages

Gun

The electrostatic spray gun has a built-in electrostatic generator, which ensures even coating application and effectively prevents electrostatic backflow during operation of the automatic powder coating system.

CE certificate

CE-certified electronic components guarantee the reliability of the high-voltage multiplier circuit and comply with the stability standards for industrial powder coating equipment in professional powder coating systems.

Outstanding component quality

The precision coating control circuit ensures high transfer efficiency coating with fast powder deposition, supporting both manual powder spraying and automated powder coating processes.

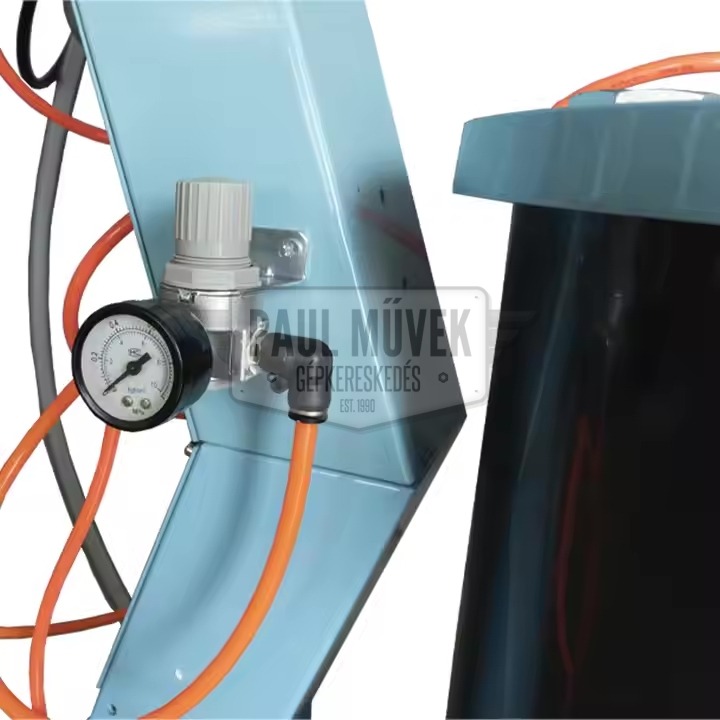

Air handling

The dual central air pump system improves the control of the atomised air flow, optimises the uniformity of powder application and increases the powder utilisation rate in industrial powder coating processes.

Construction

Stainless steel powder hopper with fluidised powder distribution plate, which ensures high powder flow capacity and has an easy-to-clean powder coating system that facilitates maintenance operations.

Paints

Compatible with multi-coloured powder coating materials, including epoxy powder coatings, polyester powder systems and metal powder coatings, providing quick colour change options for versatile powder coating applications.

Technical data

- Input voltage: 220V-240V / 1PH

- Power: 50W

- Output voltage (adjustable): 0-12V

- Pneumatic voltage: 24VDC10W

- Air pressure parameters

- Input air pressure: 0-8 mps

- Output air pressure: 0-5 mpa

- Spray gun parameters

- Mains frequency: 50-60 Hz

- Input current: -0.5A

- Output high voltage: 0-100kv

- Output weight: 400g

- Maximum output powder: 290 g/min

- Tank size: 60L

- Net size: 400*450*1020 mm

- Packaging dimensions: 450*500*1070 mm

- Net weight: 40 kg

- Packaging weight: 55 kg