Description

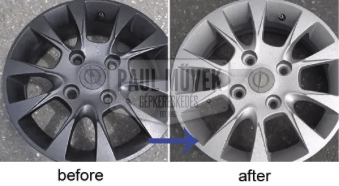

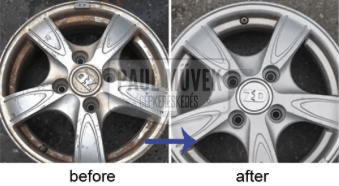

RB7 Automatic shot blasting machine from PMJ in Poland. The perfect choice for paint removal and paint preparation on wheel rims.

The RB7 shot blasting machine is a smaller version of our flagship RB11 shot blasting machine, which automates – and thus significantly facilitates – the shot blasting process. Contrary to stereotypes, blasting with the S110 medium does not result in a much rougher surface than sandblasting. At a pressure of 7 bar, the S110 shot blasting is equivalent to sandblasting with a grit size of 0.2-1.2, which results in a surface roughness of 28-35 um on aluminium surfaces. thus ensuring very good adhesion for powder coatings, for example, without the need to level the surface with a primer coat.

No compressed air is required for operation.

The shot blasting machine is an automated, labour-saving system that significantly simplifies the blasting process for wheel cleaning and finishing. The shot blasting machine gives the surface of alloy wheel rims a roughness that ensures good adhesion and perfect powder coating application.

Applications

- Wheel rims – Steel, aluminium and even truck and bus rims are no problem.

- Brake calipers – Thanks to the spacious basket, up to 30 brake calipers can be cleaned in a single blasting and cleaning operation.

- Automotive turbines – The shot blasting machine is also ideal for cleaning turbines, significantly speeding up and facilitating the process.

- Other – Generators, suction nozzles, housings and much more

Average blasting times

- Bare rims – 5 minutes

- Painted rims – 10 minutes

- Brake calipers – 12 minutes

2 OPERATING MODES

Our device stands out for its robustness and reliability, which makes it the driving force behind many refinishing and surface treatment companies!

Car wheel rims that require the removal of old paint are placed on a special hanger that rotates around its own axis and along its track, allowing the paint to be removed even from the most difficult to reach places.

Other parts that need to be cleaned by sandblasting are placed in a sturdy basket, which is rotated so that all parts can be thoroughly cleaned.

In this mode, the rim is placed on rollers that rotate the rim, allowing for quick and accurate cleaning.

All parts that cannot be placed on rollers, such as brake calipers, should be placed in the basket. Thanks to its large capacity, several parts can be cleaned at the same time in a short period of time.

All parts that cannot be placed on rollers, such as brake calipers, should be placed in the basket. Thanks to its large capacity, several parts can be cleaned at the same time in a short period of time.

None of the operating modes require compressed air.

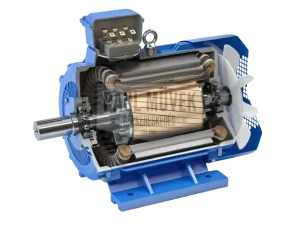

7 KW motor with inverter

Thanks to the advanced inverter, you can precisely control the speed and power of the blasting wheel, allowing you to adapt perfectly to different tasks.

Regardless of the object you want to blast, you can do the job safely and efficiently, whether it’s a delicate cover made of thin sheet metal or a wheel rim covered with hard-to-remove paint.

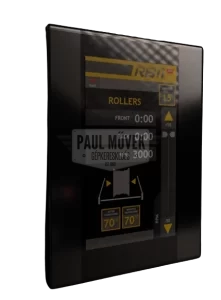

Simple control

Simple control

Thanks to the touch screen, you can easily and quickly adjust the operating parameters of the shot blasting machine to suit your requirements. The intuitive user interface makes the machine easy to operate, even for children.

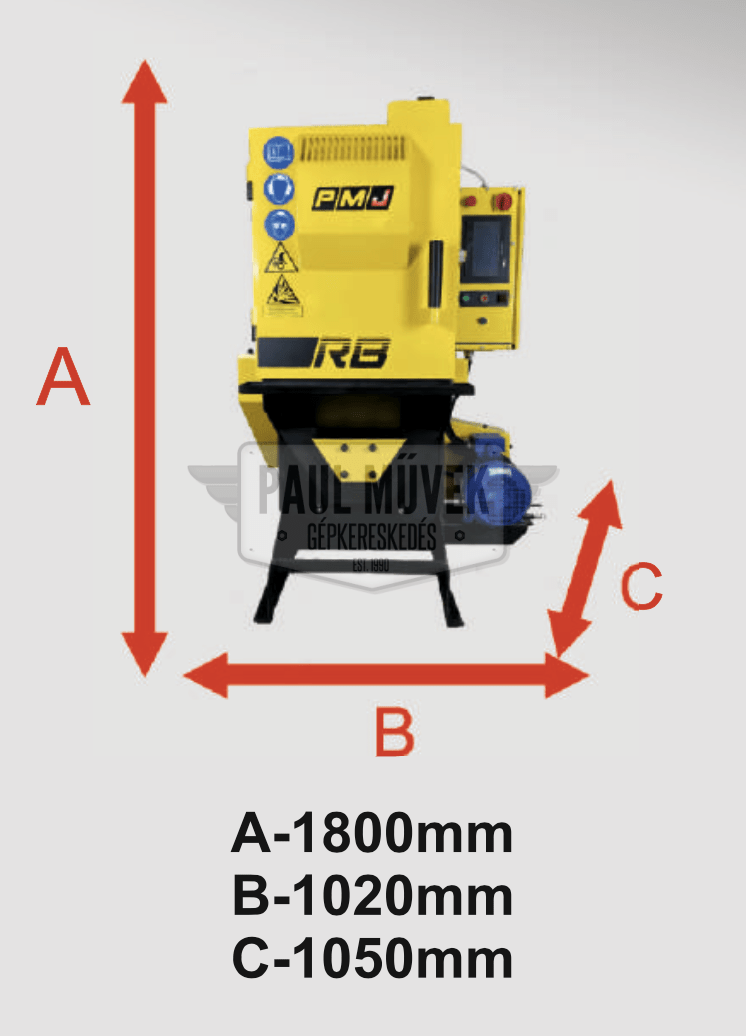

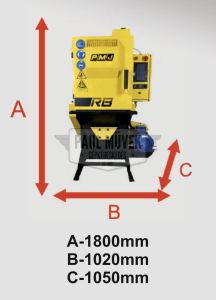

Technical data:

- Equipment dimensions: 1800 x 1020 x 1050 mm (L x W x H)

- Internal cabinet dimensions: 700 x 750 x 750 mm (L x W x H)

- Power: 7 kW

- Control system: PLC touch screen

- Intuitive control

- Roller rotation speed: Adjustable (optional)

- Blow speed: Adjustable (optional)

- Dust separator type: Dust filter: Flame-resistant filters

- Power supply: Electric

- Current: 400V / 3 PH / 50Hz (32A – 5-pin plug)

- C40A Protection required

- Weight: 850 kg

Installation requirements

- Power: 380 V / 3 phases / 50 Hz + socket combination box with appropriate fuses;

- Compressed air: –

- Ensuring the unloading process and the operating site

- The machine must be placed on stable, level ground.

Options

- PRO Version: Additional features for the Pro version (turbine inverter, explosive power adjustment)

Useful information

- What is the difference between the RB7 and RB11 shot blasters?

The main difference between the RB11 and RB7 is the size, i.e. the RB7 is smaller than the RB11. The differences can be checked in the technical data.

The second difference is that the RB7 does not have an upper suspension. The performance is the same for both blasters. The differences between the devices are clearly visible in our demonstration videos.

- How much dispersion is required for the shot blasting machine and what is the initial load?

The initial load is approximately 15 kg and the shot consumption is approximately 0.8-1 kg/hour (the shot in the machine is only replenished as it is consumed).

- Are the machines available from stock or are they made to order?

Due to the various control options, the machines are manufactured to order. The delivery time for the machines is between 1 and 4 weeks.

- What grain size do the RB11 and RB7 gunpowder sandblasters work with?

The machines are made of S090, S110, S170, S230 quality round steel gunpowder or stainless steel and can be used with gunpowder of the same size. The use of ‘sharp’ broken gunpowder causes five times more wear on consumable parts.

- Does the shot blaster require compressed air to operate?

No, compressed air is not required for the shot blaster to operate.

- Can abrasives other than steel shot be used in the shot blaster?

There are no contraindications to the use of corundum, for example, but this is not cost-effective (the machine quickly breaks up the abrasive and it is sucked out by the dust collector).

- What is the difference between a shot blaster and a sandblaster?

The difference between a shot blaster and a sandblaster lies in the abrasive used and the mode of operation. A shot blaster uses metal balls, mainly for surface treatment of metals, often in automatic operation.

A sandblaster uses sand or other mineral abrasives to treat various materials, where the sandblasting is done manually. In addition, a shot blaster can automatically clean, grind or prepare surfaces, while with a sandblaster, the operator must perform the operations manually.

- What are shot blasters used for?

A shot blaster is a device that mechanically cleans, grinds and strengthens metal surfaces by means of shot blasting. It removes rust, paint and contaminants, prepares surfaces for painting or coating, and increases the wear resistance of the material.