Description

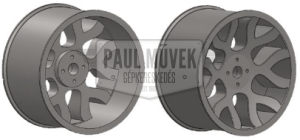

The ST6W uses wet shot blasting technology to prepare light alloy wheels for painting.

ZERO DUST EMISSION

SPECIALLY DESIGNED BLOWING DEVICE CAPABLE OF BLOWING ABRASIVES AS SMALL AS 700 MICRONS, INCLUDING SPECIALLY DESIGNED ALUMINIUM OXIDE.

SYTECH-ST WET SANDBLASTING

Dust-free wet sandblasting technology from Turkey. Tailored to the daily activities of wheel repair companies in the automotive industry.

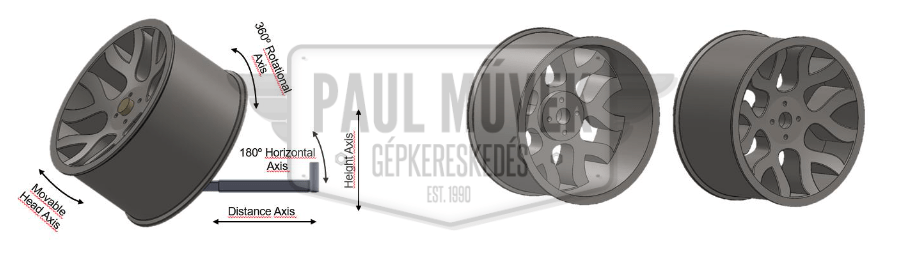

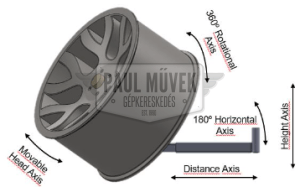

The specially designed wheel holder with 5-axis mobility allows easy access to any point on the wheel rim, ensuring that every part of the wheel is cleaned without any problems.

The SayTech wet sandblasting system is designed exclusively to help you achieve excellent surface treatment results. Thanks to the tools included in the basic package, you have complete control over the process, which improves and ensures long-term operation.

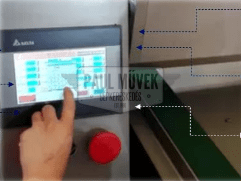

The machine is automated and very easy to use thanks to the instructions displayed on the PLC screen and the simplified operation control.

Build your system, because we don’t just offer a simple unit. If you need to grind complex wheels, just let us know and we will provide you with a great solution to clean several tonnes of wheels per day without unnecessary movement.

A great option for wheel cleaning and preparation for painting or coating processes. SayTech can be your best partner for wheel cleaning day after day.

Features:

- Dust-free wet blasting system, which does not damage the surface unlike dry sandblasting.

- 5-axis wheel holder is the best thing you can imagine, no more headaches from moving and turning wheels in the cabin

- Reliable operation

- PLC screen data supports you during operation.

- Great quality from Turkey, an affordable solution for all types of businesses to get a high-quality machine without a costly investment.

- Strong and durable materials and the system provide greater safety than the market average.

- Outstanding systems from simple units to complex solutions.

5-axis mobility allows

easy access to any point on the wheel

and adjustment to the desired operating direction

Thanks to the specially designed wheel holder,

which allows both sides of the wheel to be secured,

the inner and outer surfaces of the wheel can be machined in detail.

The PLC screen provides full control over the machine.

Maintenance notifications

Warnings and error messages

Generation of recipes for automated machines

Counting and recording of working hours

Notifications for replacement parts

Safety and security messages

The machine spreads, washes and prepares the wheel rims in a single quick and easy step, ready for painting and varnishing. This process uses water mixed with abrasive material to treat the surface of the alloy, providing an ideal surface for paint or varnish to adhere to.

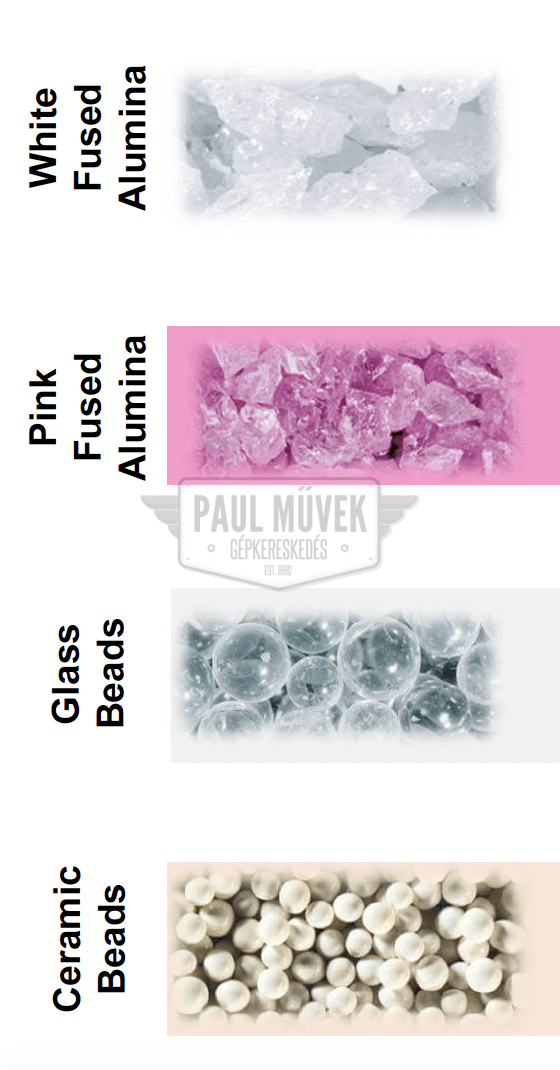

ABRASIVE / CARRIER

We supply our customers with spare parts

We provide our customers with 50 kg of glass beads as a free consumable kit for their first use of the machine.

Consumables with a specific gravity of less than 4 g/cm3 are acceptable in current wet blasting systems. (Grenades, silicon carbides, glass beads, aluminium oxides, etc.)

Consumables with a specific weight greater than 5 g/cm3, such as steel shot/grit and stainless steel shot/grit, must not be used in wet blasting systems. Otherwise, damage to the device will be considered outside the scope of the warranty.

Wet blasting machines can operate effectively with consumables with a maximum particle size of 700 microns.

Advantages of wet blasting

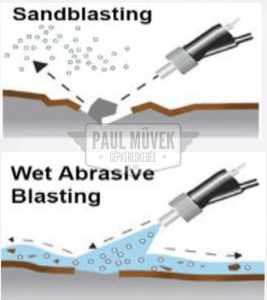

In terms of the basics, wet sandblasting is similar to sandblasting, with the major difference being that the cabin is filled with water and the blasting material is added to the water. The key to wet blasting is the surface achieved by the particles carried by the water flow. The resulting effect is unique thanks to the force exerted and the lubricating effect of the water. An electric motor-driven pump circulates the water mixed with the blasting material at a constant pressure and feeds this slurry to the blasting nozzle. Here, clean compressed air is added, which accelerates the cleaning process and, when adjusted, also refines the effect on the surface.

Wet particle blasting is not only a perfect alternative to dry processes, but also differs from sand or bead blasting in that the latter cleans by the shearing force exerted on the surface when the particles strike it. The impact results in a 90˚ rebound, causing severe surface damage and craters.

The essence of wet blasting is therefore that the final condition of the surface is ensured by the effect of the abrasive medium in the liquid stream, i.e. a smoother surface is achieved by the effect of the flowing liquid. The abrasive medium does not penetrate the structure of the material to be cleaned, so the particles do not degrade to such an extent that dust is generated, unlike in dry blasting, where the surface is formed by the shearing forces of the impacting abrasive medium.

The turntable is designed so that the operator does not have to lift, hold or move the workpiece; all they have to do is turn the turntable in the right direction while the shot blasting continues.

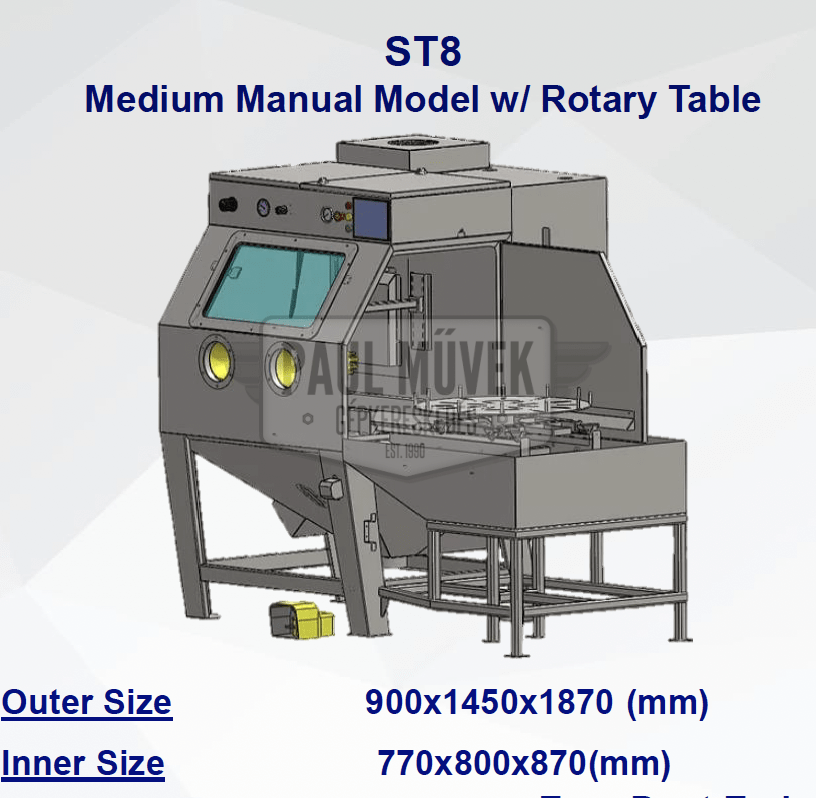

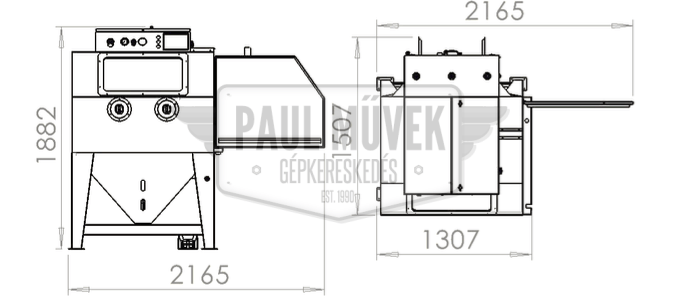

Technical data:

- External dimensions: 1307 mm x 1507 mm x 1882 mm (h)

- Cabinet dimensions: 1150 mm x 1000 mm x 850 mm (h)

- Electrostatically painted, 100% stainless steel frame and cabinet

- Leak-proof laser welding

- Manual wet blowing

- Suitable for blowing 15-26 inch wheels weighing up to 50 kg

- Portable wheel holder with 5-axis movement. Removable if multiple cabins are required.

- Processing capacity: 3-4 m2/hour

- Powerful LED lighting inside the cabin 2×27 W=54 W

- Tempered screen window glass

- Automatic window wiper system

- Manual side door

- Jet-Pulse self-cleaning stainless steel cartridges

- PLC intelligent touch screen computer system

- Electric pedal-operated blasting process

- Carbide nozzle

- Aluminium sandblasting gun

- Rinsing gun

- Fully automatic sludge discharge system

- Safety and protection package

- Water level sensor

- Improved suction system developed to prevent clogging.

Installation requirements

- Power supply: 380 V / 3 phases / 50 Hz + socket combination box with appropriate fuses;

- Compressed air: 6-10 BAR constant pressure (at least 1⁄2” PPRC hose)

- Ensure the unloading process and the operating site

- The machine must be placed on stable, level ground.

- Preparation of mains water and waste water pipes (the waste water outlet must be at least 1” in size).

WHY CHOOSE WET BLASTING?

- Wet sandblasting is an innovative technique that sprays an abrasive mixed with water onto the surface using pressurised air, utilising the force of the liquid flow to effectively clean corners and crevices without damaging the original surface texture.

- The much better, smoother surface does not require pre-cleaning or deburring. It is characterised by dust-free operation and environmentally friendly technology.

- Zero heat distortion

- Homogeneous surface quality

- No fingerprints

- No media penetration/impregnation into the surface (no contamination)

- Cleans with flow

- Reduced abrasive costs thanks to longer service life

- Wider range of surface treatments available

- Gentle or abrasive effects can be achieved by changing the material and blowing pressure.

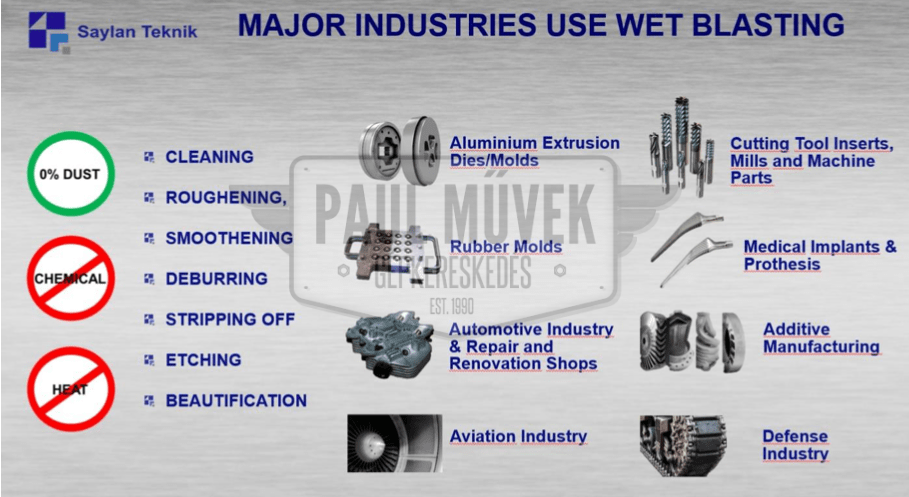

What surface treatments are performed with wet blasting?

Degreasing:

The degreasing process removes grease, oil and other contaminants from surfaces. Water is used during sandblasting to achieve a more uniform surface quality, reduce dust and ensure a more controlled and environmentally friendly cleaning technique.

Wet sandblasting and degreasing work well together to prepare surfaces for painting, coating or other treatments, ensuring good adhesion.

Removal of old paint, thicker coatings and contaminants:

Wet sandblasting is one of the best methods for restoring surfaces that have been painted or coated with one or more layers. With the use of the right abrasive and water, it allows you to renew the material without damaging the underlying surface layer.

The wet sandblasting process restores the surface to its pre-painting or pre-coating condition.

Smoothing rough surfaces:

Wet sandblasting is often used to create a more even surface on areas with high roughness and poor uniformity.

By providing a balanced, contamination-free surface, it contributes significantly to the success of subsequent processes such as painting and coating.

Roughening smooth surfaces:

Surface roughness plays an important role in many mechanical properties, such as friction and adhesion. Wet blasting is one of the most popular methods for achieving a balanced surface roughness. Wet blasting is even used safely for roughening the surface of implants used in the human body, as it minimises the risk of abrasive material embedding in the surface.