Description

220 Volt/250 Watt Tire Grooving Iron Tool

Info

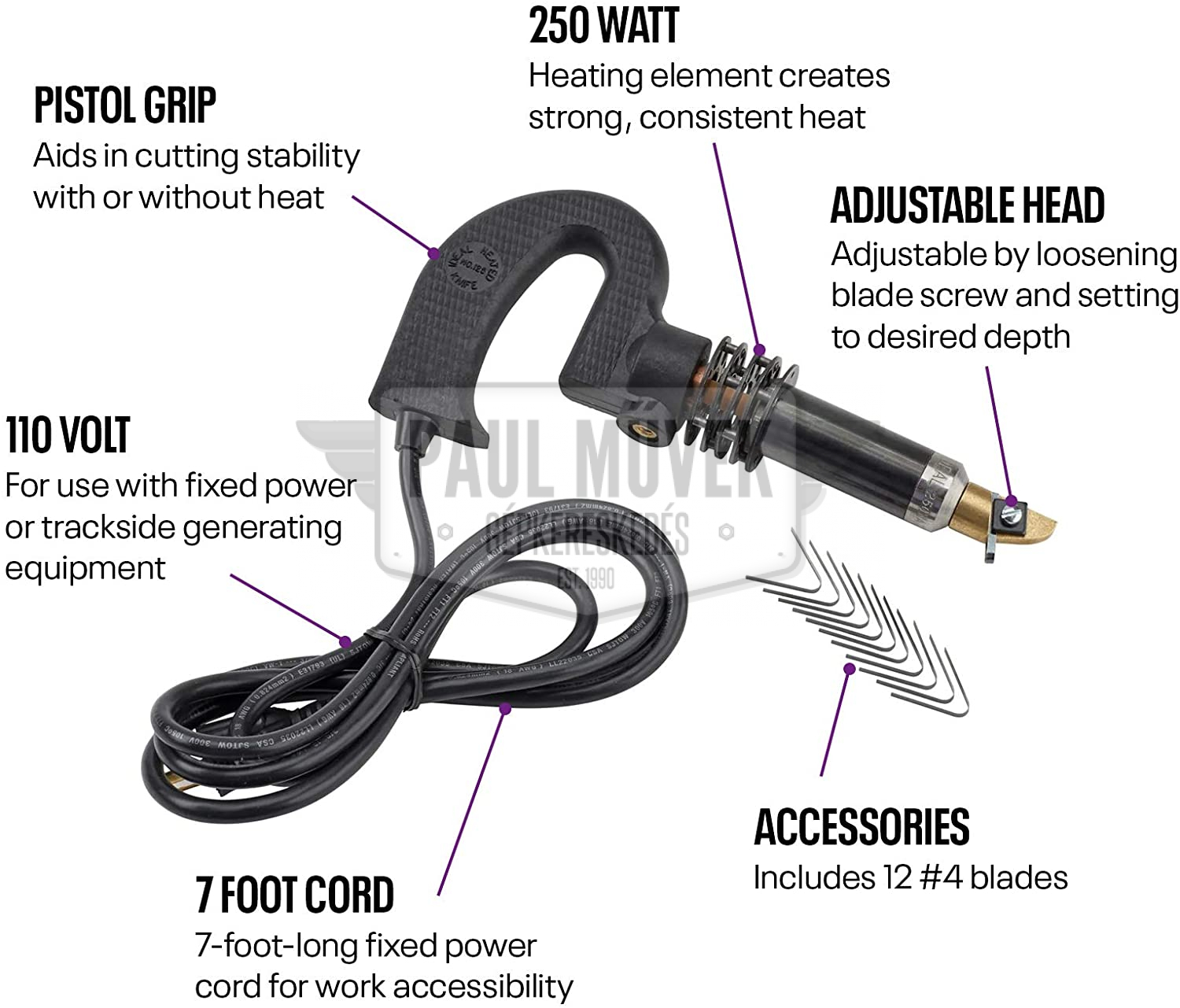

- 250-watt heating element creates strong, consistent heat

- 220 Volt (These are generally used internationally)

- Heating capacity of 250 watts

- Cord length of 7′

- Consists of #4 Head and (12) #4 Blades (.215 wide)

- Works great for Race Car Tires, Off-Road/Mudd tires, Go-kart Tires, Truck Tires, and many hobbies and crafts

- ***Please note that the 220v groover is intended for international use and has a standard US 110v plug installed***

- 7-foot-long fixed power cord for work accessibility

- Perfect for grooving and siping tires used in dirt motorsports

- Pistol grip design aids in cutting stability with or without heat

- Includes #4 tool head and blades, other sizes available

- Accepts all Speedway Motors and Ideal brand tool heads and blades

- Multi-blade siper head can be used to cut six sipes at once

- Depth of sipe adjustable by loosening blade screw and setting to a desired depth

- Grooving blades can be turned upside down to sipe the tire

Ideal tire groover knives are designed and constructed for long service life, as well as ease and speed of operation. The ideal tire groover has engineered glass reinforced nylon pistol grip handes are light and cool for comfortable operator use. Solid brass head keeps the heat “just ahead” of the grooving blade. This pre-conditions the material to be cut and makes for speed, ease, and accuracy.The depth of the cut is controlled by the adjustable blade.

When using the Ideal tire groover, we have found that using baby powder on the tire aids in the process of grooving.

Maximize Your Tire’s Traction by Adding Grooves and Sipes

If you race on dirt you know that track conditions change throughout race day and many will ask how to increase traction on tires. From a high grip surface that can be wet and slinging mud to a shiny black or even hard and dusty surface as the laps pile up and the sun goes down, tire traction can change dramatically. While there are different tire compounds you can choose from to aid in traction depending upon the track’s bite, one thing many experienced racers do is modify their dirt tires by adding grooves and sipes to the tread blocks using a heated tire grooving iron tool with a specific cutting head and blade attachment.

What is tire siping and grooving? Well, grooving is just that, cutting grooves in the tread where you are removing rubber, while siping is where you make a thin cut (like a razor blade) but no material is actually removed. These cuts can be made in various widths and directions to enhance traction and get the tire up to temperature faster but can also be used to increase a tire’s longevity by helping it run cooler too. It is all in how the tire is cut.

Learning how to cut a tire with a tire groover and sipe your own tires is a bit of a black art, but a good racer will keep a logbook of modifications and can reflect on past track conditions to see what size groove and angle worked best previously. The same goes for tire siping. Often you can lean on a fellow racer for grooving and DIY tire siping advice or reach out to the tire manufacturer for suggestions on how its tire products react to certain grooving and siping cuts. Regrooving tires that have been sanded down and brought back to life is one way to save some money in your race budget too versus buying new rubber for your race car.

Built Tough to Handle Any Tire

Grooving tires and siping tires on your dirt racer takes some effort, but the Ideal heated Knives 125 tire groover tool is built to take it. Ideal starts off with a robust heating element that outputs a consistent heat and housed it in a tough steel shell with chrome-plated steel tip.

The fiberglass-reinforced polymer handle keeps your hands safe from the extreme heat found at the head of the cutting tool. Ideal then added a fully grounded UL-listed power cord that is a generous 7-feet in length.

This tire cutting tool is designed to work with all Ideal Heated Knives and Speedway Motors brand tire grooving iron heads and blades that we carry. This kit includes a #4 head and matching #4 blades. Additional head and blade sizes are available. Additionally, using our optional multi-blade siper head instantly turns the Ideal tire groover into a tire siping tool that makes quick work of your tread blocks.

Grooving and Siping Your Tires Could not be Easier

We carry a full lineup of cutting blades and heads (the heads and blades must match in size and used together) for the Ideal tire grooving iron. You will install the appropriate size head into the tool first, followed by the matching cutting blade. Set the depth of your blade before plugging the iron in and it gets hot. Generally, you will want your sipes to be 1/8-inch to 3/16-inch in depth and no more than 1/2 the depth of the tread block.

Most racers will find having more sipes on the front tires and less on the rear is the best combination. Sipe spacing is also determined by the size cutting blades used, with the further apart the sipes the cooler the tire will run. When cutting your grooves, you want them to be at full depth. The width of the grooves and direction will vary depending upon track conditions and whether you are grooving a front or rear tire (rear tires are usually grooved straight across and front tires are grooved at a slight angle to improve forward bite and warm the tire more quickly).

Make the Move and Start Improving Your Tire’s Traction Today

While grooving your tires takes some trial and error and an ability to read a track surface, in the end, grooving and tire siping dirt track racing tires with additional grooves and sipes is just another tool in a racer’s toolbox of tricks and tips to help them get to the front of the pack and stay there until the checkered flag drops. It does not matter if you are racing a Late Model or Sprint Car, doing some competitive rock crawling, rally racing or even mud drags, modifying your tires with the Ideal tire grooving iron kit is sure to benefit your racing program by providing the ideal tire, making your tires grip the surface better and put just the right amount of heat into them.

Application

Sanctioning bodies that allow tire grooving/siping (in specific classes) include IMCA, Wissota, USRA, USMTS, UMP

Notes

- Install the head and set the blade to the depth of cut needed before plugging in the groover

- Plug the groover in and allow it to warm up for five minutes before you start grooving; our tabletop tire grooving iron stand is suggested for warm-up and cool down

- Always store tool facing up/handle down in a vertical position while in use to minimize temperature transfer to the handle

- Monitor the temperature of the tool and unplug it as needed to regulate the temperature

- This grooving iron will reach operating temperature quickly due to the extreme heat created and will groove before reaching its max temperature

Tire Grooving Tips

- Sanding the mold nubs off the tread before grooving or siping is suggested if the nubs are large; a tire grinder with a 60-grit sanding pad works well for this

- Most tires are easier to groove or sipe with the tire mounted and inflated to normal pressures; this is especially true with thin wall racing tires

- Complex tread designs can be marked out with a tire marking paint pen or paint stick

Circle Track specific Grooving and Siping Tips

Tire Grooving

- Grooves around the circumference of the tire will add side bite and help cool the tire

- Grooves across the tread will add forward bite and help warm up the tire

- Rear tire grooves and sipes across the tread typically work best when straight across the tread (90 degrees to the circumferential grooves)

- Front tire grooves and sipes across the tread typically work better at a slight angle and when viewed from the top of the right front tire the grooves will angle from right front to left rear

Tire Siping

- Sipes have a similar effect as grooves and are primarily used to warm up the tire

- Sipes around the circumference do not provide much if any cooling effect since they are not open for air to flow through like grooves are

- 1/8-inch to 3/16-inch sipe depth works well for most tires.

- Adding more sipes which are closer together will increase the tire temperature and will add grip as long as the tire is not overheated

- If a tire is overheated and blisters the sipes need to be spaced further apart and possibly a shallower depth of cut should be used

- More sipes are typically used on front tires to help them heat up and less sipes on rear tires, especially the right rear

Made in the U.S.A.