Description

The VIXEN Aqua Wheelblaster uses Vixen’s wet blasting technology to finish and provide a key for alloy wheels.

VIXEN Aqua Wheelblaster machine blasts, washes and prepares alloy wheels in one quick and simple step ready for painting and lacquering. This process uses water mixed with abrasive to surface treat the alloy and provide an ideal surface for paint or lacquer to adhere to – in just 3 minutes!

The use of water ensures no media is impregnated onto the alloy wheel. The water also provides a washing action and does not strip the wheel back to bare metal. The wetblasting process used in the Aqua Wheelblaster does not need a specific room for siting, eliminates the risk of dust and combines all of the preparation process in one cabinet – ideal for the workplace.

This machine pictured is with our optional extra wheel lift (see below).

VIXEN Aqua Wheelblaster Features:

- Dust – free process

- Optional Pneumatic lift complies with health and safety

- Internal spigot ensures ease of handling and loading

- Compact cabinet design

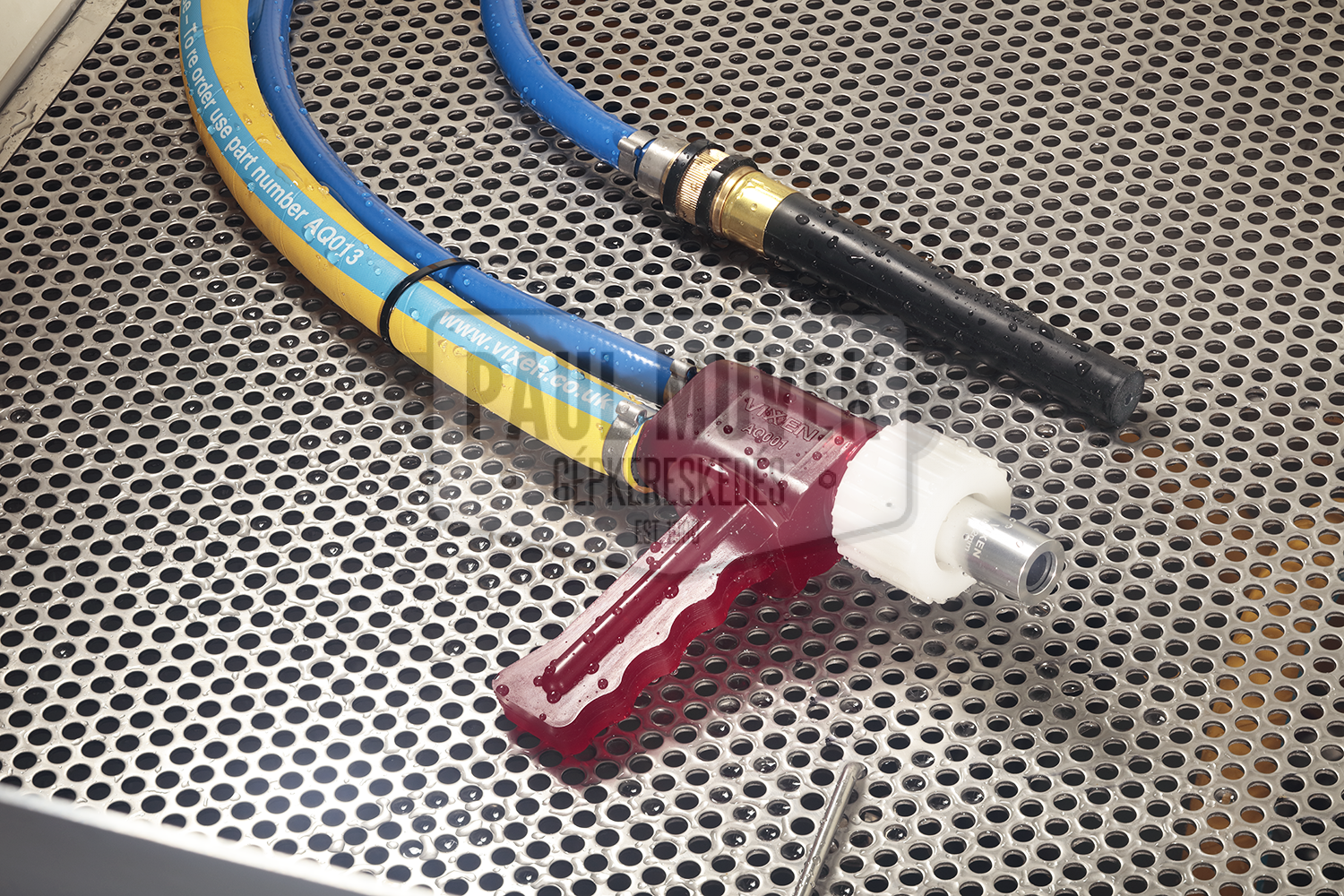

- Blow off gun to remove excess water and media ready for painting

- Combines six processes in one machine

- Wheels can be prepared in less than three minutes

- After processing, the original paint of the wheel will be totally clean and perfectly etched ready for recoating with paint.

VIXEN Aqua Wheelblaster Optional Extras:

Hydro cyclone

The hydro cyclone is designed to separate water from the blasting media to around 90%. It is ideal when emptying the machine or changing abrasives.

Mini Tumbler Barrel

The mini barrel offers the option to be able to blast many small parts (i.e. nuts and bolts) evenly. When blasted, the parts can be easily removed by removing the barrel with the grab handles and tipping out the par.

Turntables

For easy manoeuvrability within the blast chamber a stainless steel turntable can be fitted, and for larger/heavier components a roll in-roll out trolley with rails external to the cabinet can be fitted for easier component loading.

Armholes – Bellows

For some applications where manoeuvrability within the blast chamber is required, bellow type armhole ports are recommended. These offer the operator easy access to high components or where mobile turntable.

Blast Gun Holder

Fitted inside the cabinet is a blast gun holder, enabling the operator to present the components to the blast nozzle.

Vapor Blasting using a Closed Loop

Closed loop implies that the machine will not require a drain nearby and will not consume large amounts of water. The basis for a closed loop system is a large filter unit which filters the liquid sufficiently so it may be used for the rinse gun.

VIXEN Aqua Wheelblaster in action!